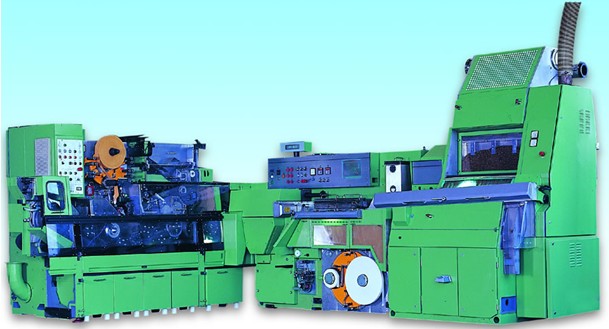

PROTOS70 Cigarette Maker, Cigarette Making Machine

This product is for making filter cigarette with different diameter and length. It consists of tobacco rod maker, filter assembler, and tray loader. It can be linked with downstream cigarette packer by tray loader and tray unloader, or it can be directly linked with cigarette packer by link-up system.

Features:

- High quality of cigarette output: it has functions of filter missing detection, air leakage

inspection and loose-end detection to ensure qualified cigarette output.

- Complete trouble shooting system: it has function of fault alarm, fault dispaying and

fault diagnosis which can help shooting the trouble effectively.

- Perfect cigarette weight control system: by adopting microwave weight control

system, it can control the cigarette weight precisely and thus save cut-tobacco consumption.

- Low wastage: this machine is with stable running performance and high operating

efficiency, and as the result, the wastage ratio is extremely low and running cost of

this machine is reduced.

Technical Specifications:

- Capacity: 7,000 cigs./min. (for king sized cigarete);

- Tobacco rod speed: 490 m/min.;

- Cigarette diameter: 5.4mm~9mm;

- Cigarette length: 65mm~120mm;

- Filter length: 10mm~25mm (one filter cut into six) or 15mm~35mm (one into four)

a high-speed cigarette making and filter assembling group, is made under introducing the technology of PROTOS 70 from Hauni Maschinebau AG Germany by China National Tobacco Corporation, in the way of Technology-Trade combined cooperation in 1992. It is manufactured by Changde Tobacco Machinery Co., Ltd after technology digestion and absorption, innovation and improvement, having features as follows:

1. Stable production: The cigarette output is 7000cig/min, the max. tobacco rod forming speed is 490m/min.

2. Ensure high quality cigarettes, and automatically detect air leakage, loose end, filter missing, soft spots, hard spots, too light, too heavy and other substandard cigarettes in the production process.

3. Complete trouble- shooting system: It can automatically test the faults when it goes wrong, and then raise the alarm, display the faults, stop running to analyze and make statistics on faults.

4. Complete weight control system: It measure cigarette weight with high-precision control, and it can offset automatically to save cut tobacco, greatly reducing the production cost of cigarette factories.

5. Automatic monitoring performed in manufacturing process: It can automatically analyze, make statistics and management for production data, and output the data in report forms.

6. Convenient and efficient human-computer interaction system.

7. With small volume and weight, less area is possessed.

|

Rated output capacity |

7000cig/min |

|

Rated rod forming speed |

490m/min |

|

Cigarette length with filter |

65mm~120mm |

|

Cigarette length without filter |

54mm~90mm |

|

Filter length |

20mm~24mm (1rod/6) |

|

24mm~30mm (1rod/4) |

|

|

Cigarette circumference |

21.7mm~28.26mm |

|

Compressed Air consumption |

34 m3/h |

|

Working pressure |

≥0.6mpa |

|

Air exhausting (Central dust extraction) |

2700 m3/h |

|

Rated power for electrical system |

44.5kW |

|

Net weight |

8730kg |

|

Overall Dimension (L×W×H)mm |

5072×3928×2600 |