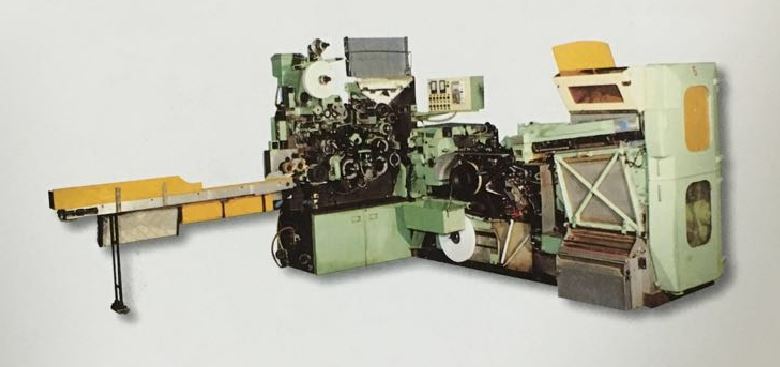

MOLINS MARK 8 CIGARETTE MAKING MACHINE

we're the cigarette machine's manufacture, providing MK8, MK9, HLP2 cigarette packing machines and spare parts, cigarette materials. super quality and competitive price.

MOLINS MARK 8 CIGARETTE MAKING MACHINE = Cigarette Rolling Machine + Filter Assembling Machine

a. Cigarette Rolling Machine: To wrap cut-tobacco in cigarette rolling paper and cut into pieces

b. Filter Assembling Machine: To combine filter with tobacco rod into finished cigarette which can be consumed already

INTRODUCE

This MK8 cigarette making machine is dedicately designed for KING SIZE Cigarette production with a speed of 2,000 cigarette per minute. Modification tools are needed to make another type of cigarettes. The finished goods of this machine will move on to cigarette packaging machine to pack cigarettes into packets, then into cartons. This machine is widely used in Asia, Middle east, Africa and south America markets.

Before manufacturing, cigarette size and machine capacity need to be fanalized as following:

a. Cigarette length

b. Cigarette diameter

c. Machine speed

d. Filter length

e. Cork tipping paper width

f. Cigarette tray size of both inner and outside

MK8 cigarette making machine TECHNICAL DATA

| Output: | 2000cig/min |

| Rod Speed | 140-175m/min |

| Cut-off Speed | 2000-2500r/min |

PRODUCT DIMENSION

| Filter Cigarette Length | 65- 120mm |

| Rod Cigarette Length | 45-90mm |

| Rod Cigarette Diameter | 6.3-9.0 mm |

| Filter Plug Length | 60-159 mm |

| Filter Tip Length | 15-30mm |

| Filter Tip Diameter | 6.3-9.0mm |

| CorkPaper Length | 13-45mm |

AMBIENT CONDITIONS

| Air Pressure | 6×105pa |

| Working Pressure | 4×105pa |

| Supply Voltage | 380±38 V(3 phases) |

| Lighting Voltage | 220±22V |

| Frequency | 50HZ±1HZ |

MACHINE WEIGHT

| Maker | 3050KG |

| Plug Assembler | 1800KG |

| Total power | 17 kw |